We are used to a personalised digital experiences. From digital advertising to digital identities. However, everyday real-world products are still made for the masses thanks to mass manufacturing at scale from the last industrial revolution.

With Additive Manufacturing, it is time to usher in an era of mass personalisation.

At Structo, our mission is to build the additive manufacturing tools necessary to enable a global infrastructure built to deliver personalised products at a mass scale.

Whether it’s dental treatments, hearing aids, or athletic footwear, we are building towards a future that is completely personalised.

To deliver on our mission, we’ve built a deep expertise in the 4 core areas of additive manufacturing.

With these expertise, we get to design solutions to solve specific manufacturing problems in different verticals.

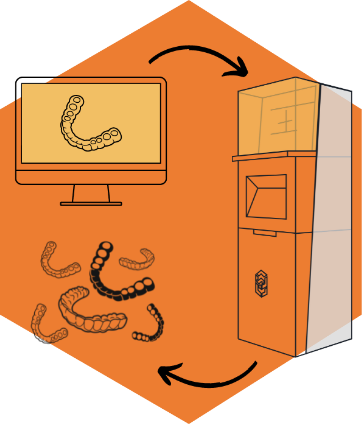

PRINTERS & AUTOMATION

SOFTWARE

MATERIAL SCIENCES

WORKFLOW

The dental industry remains a leader when it comes to personalised manufacturing. The very first industry to embrace additive manufacturing at scale, the industry found a way to deploy the technology as a production tool in a highly scalable manner.

ST-01

An MSLA-powered 3D printer for the high throughput production of dental appliances in dental and orthodontic laboratories.

LEARN MORE

ST-32

A semi-automated 3D printer for round-the-clock production of high volume clear aligner models in dental and orthodontic laboratories.

LEARN MORE

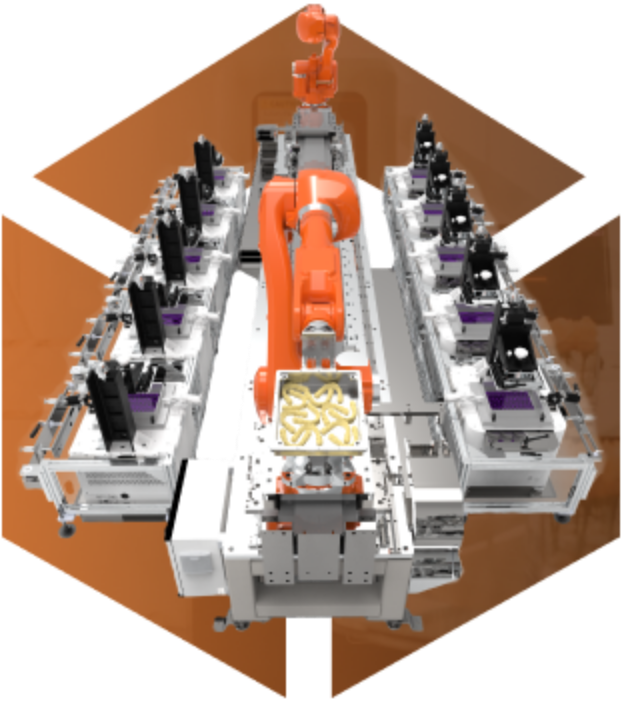

BESPOKE AUTOMATION

6-axis robotic arms, quality control stations, the possibilities are endless with our custom solutions for a true mass customisation digital factory.

LEARN MORE