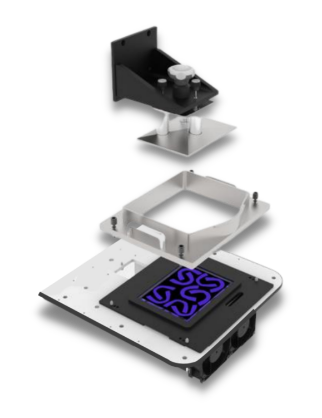

A high-tech way of saying ridiculously high throughput.

MSLA-powered 3D printers are capable of achieving speeds far superior than existing SLA, DLP or DLS printers. That translates to higher throughput, quicker turnaround and lower cost per part for our customers.

LEARN MORE

Formula follows function.

We've formulated a range of light-activated, purpose-built liquid resins for various applications to work hand-in-hand with our hardware technology.

LEARN MORE

Hardware is only half the story.

Forming the central nervous system of your digital factory, our software solutions allow you to take full advantage of big data optimisation, remote control systems and diagnostics analytics. *Please contact us regarding custom integration inquiries.

LEARN MORESee how we take these innovations and transform them into solutions for real world problems.

OUR SOLUTIONS